A systematic approach to stretch tent pegging / staking

Correct pegging procedure is fundamental to the safe and proper function of our stretch tents: when a stretch tent is subjected to the forces of wind, it takes on a new shape, which significantly affects the forces which the pegs / anchors must resist in order to keep the stretch tent from collapsing.

Engineering principles for single staking

This section presents a general explanation of some of the engineering principles which relate to the best stake position for our stretch tents. By equipping stretch tent installers with this technical information, stretch tent staking should be enhanced.

-

-

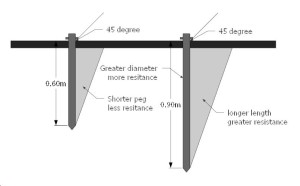

- The larger the stake diameter the greater the holding power:

RHI supplies 25mm pegs / stakes: this is the minimum diameter stake that should be used, if operators are sourcing their own pegs / stakes. - The deeper the stake, the greater the holding power:

Stake pull out strength is directly related to the peg / stake depth: RHI supply 1m stakes with a nut welded 10cm from the top. The stakes should penetrate the ground surface the full 90cm up to the nut. - Guide ropes attached to stakes at 45°:

Guide ropes attached to the stake at a 45° angle produce vertical forces equal to lateral forces, which is the ideal balance.

- The larger the stake diameter the greater the holding power:

-

-

-

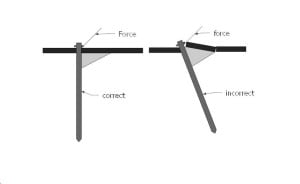

- The straighter the stake the greater the holding power:

While many operators stake at an angle, stakes in fact have a greater holding power when pegged vertically.

- The straighter the stake the greater the holding power:

-

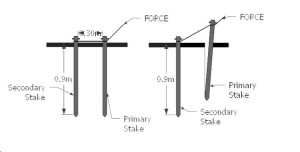

Double staking

Double staking is the practice of driving another stake a short distance behind the primary stake and close-tying both stakes together. This is beneficial where there is a likelihood that the primary stake might not be sufficient by itself, or when the particular guy rope location is a critical link in the stability of the tent.

-

-

- Staking the secondary stake the correct distance away:

A rule of thumb for double staking suggests that the distance between stakes be equal to one-third of the depth of the primary stake in the ground.

- Staking the secondary stake the correct distance away:

-

-

-

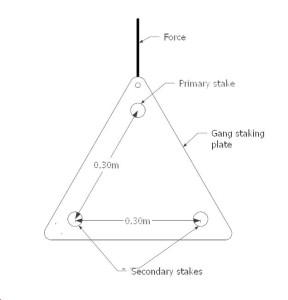

- Gang staking

A staking technique related to double staking, in that it also increases staking capacity, is called gang staking. This involves the use of a rigid ground plate with holes punched in it for the stakes.

- Gang staking

-

*Reference: Information taken and adapted from The IFAI Procedural Handbook for the Safe Installation & Maintenance of Tentage Fourth addition.

Estimating pull out capacity of tent stakes

A method for estimating pull-out capacity for tent stakes is descried in this section. The method is based on results of 489 stake pull-out tests which were conducted at nine different field sites.

The method estimates the stake pull-out capacity for a “baseline” stake. The baseline case for a tent stake is as follows:

-

-

- Stake diameter is 1.0 inch / 25mm

- The side of the stake is smooth

- The steel stake is driven vertically

- The stake is embedded (driven) 36 inches /914mm in the ground

- The load is fastened at 2 inches / 50mm above the ground surface, and

- The load is pulled at a 45 degree angle.

-

Estimates of pull-out capacity for baseline case

The strength of the soils is an important detail for estimating pull-out capacity. The penetration resistance offered by the tent stake during installation provides a rough miscue for the strength of the soil and is based on the average penetration of the stake per blow (for the first 20 inches of embedment) with a 16 lb / 7.25kg sledge hanger using a normal swing. The table below provides a rough relationship between penetration resistance, soil consistency, and pull-out capacity for a baseline case.

| CONSISTENCY | SOIL RESITANCE THUMB | STAKE PENTRATION RESISTANCE (mm’S) | PULL OUT CAPAICITY FOR BASELINE (KG) |

|---|---|---|---|

| HARD (very Dense) | Indented with difficulty with thumbnail | Less than 5mm’s | 1134kg |

| VERY STIFF(Dense) | Readily indented with thumbnail | 5-12mm | 726kg |

| STIFF (Medium Dense) | Readily indented with thumbnail but penetrated only with great effort | 12-38mm | 363kg |

| MEDIUM (Medium) | Can be penetrated several inches with thumb with moderate effort | 38-76mm | 181kg |

| SOFT (Loose) | Easily penetrated several inches by thumb | 76-152mm | 91kg |

| VERY SOFT(Very Loose) | Easily penetrated several inches by fist | Greater than 152mm | 45kg |

*Reference: Information taken and adapted from The IFAI Procedural Handbook for the Safe Installation & Maintenance of Tentage Fourth addition.

Get in touch with our experts for assistance with all your questions.